Building Statistics

| General Building Data | |

| Name | Life Science Buidling |

| Location | North East of the United States |

| Occupant Name | Educational Institutes |

| Occupant Category | III - IBC 2006 |

| Size | 174,500 square-foot |

| Number of Floors above Grade | 5 stories |

| Heights | 91 feet |

| Construction Dates | September 2008 - August 2011 |

| Approximate Cost | $91.6 million |

| Project Delivery Method | Design-bid-build |

| Project Team | |

| Owner | Education Institutes |

| Architect | Bohlin Cywinski Jackson |

| Project Manager | PML Project Management |

| Construction Manager | Bond Brothers, Inc. |

| Structural Engineer | Ryan-Biggs Associates, P.C. |

| MEP/Lighting/Telecom-data Engineer | vanZelm Heywood & Shadford, Inc. |

| Lighting Design/Sustainability | Atelier Ten |

| Laboratory Planner | Jacobs Consultancy, Inc. |

| Civil Engineer | Engineering Ventures, PC |

| Landscape Architect | Saucier + Flynn |

| Safety/Fire Protection | Philip R. Sherman, PE |

| Cost Estimator | Becker & Frondorf |

| Audio/Visual/Security | Sextant Group |

| Greenhouse | Agritecnove |

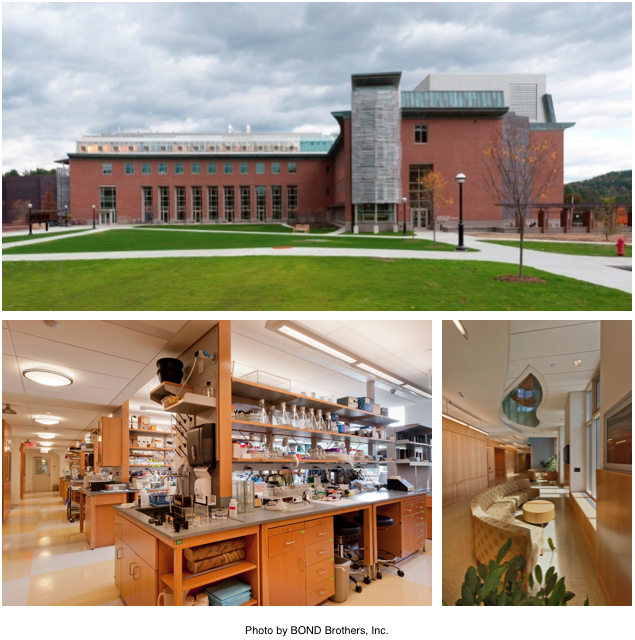

Architecture

Life Science Building provides for the exploration of Molecular and Cellular Biology, Ecology, and Evolutionary Biology. The size of building is 174,000 square-feet to pro-vide an interactive, collaborative, state-of-the-art home for researchers from young tal-ented students to world-class scientists.

The main goal of this project is to create a building that is optimized in both aesthetic and function.

The building accommodates a 4,000 square-feet Nuclear Magnetic Resonance suite, eight classroom laboratories, a 200-seat auditorium, two 80-seat and two 30-seat class-rooms, and 30 teaching and research laboratories with faculty offices.

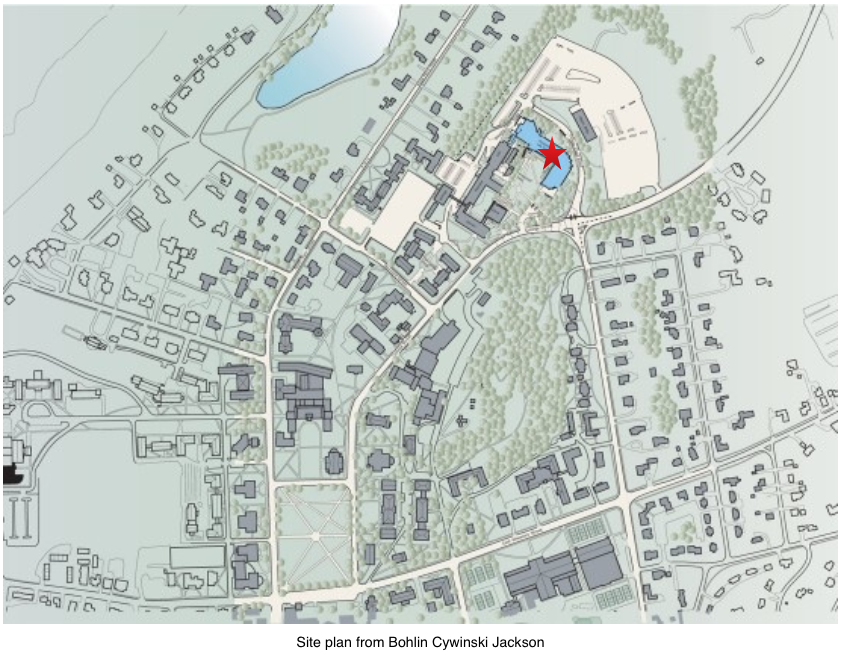

The project is located on the northern end of campus in a college town in the north east of the United States.

The building is divided into 3 sections: west, north, and east. Each section is clearly distinguished by the function. The auditorium is located on the west side. On the north side, most laboratories are located in the first, second, and third floor and the green-house is located on 4th floor. The East side has laboratories on the first floor and the second and third floors are mostly for office space.

“At its core it was designed to be a building for modern life sciences that had a flow and a tempo and a flexibility that allowed people to come together in teams, work together, and solve problems of great impact, “: said one researcher. Laboratories and common spaces promote the interaction of idea and techniques between students and faculty. Natural light is reflected on the curving staircase to create warm welcoming feel to peo-ple. Laboratories are placed on the first floor to be more accessible.

The building adapted the state buidng code based on 2006 International Building Code.

- International Building Code 2006

- International Plumbing Code 2006

- International Mechanical Code 2006

- International Energy Conservation Code 2006

- National Electrical Code 2008

- International Residential Code 2006

The building is zoned to be in industrial zone (I-zone).

Historical RequirementsThere are no unique historical requirements for this project.

Building Enclosure

Building facadessystem is designed to save the energy of the building. The envelope consists of spray-on foam insulation and air barrier along with the triple-glazed aluminum curtain walls. The exterior brick veneer is supported by the relieving angles, which is an innovative relieving angle support allowing the insulation to run continuously behind the angles. This envelope design diminish thermal exposure and provide weather tightness throughout the year.

RoofingRoofing This project has a 6,400 square-foot greenhouse located on the roof of building. A separate concrete topping slab is designed over the structural concrete roof slab where the greenhouse is located with a waterproof membrane and rigid insulation are in-stalled between concrete slabs. The other roof area is designed for a green roof and it is constructed with layers of soil waterproof membrane and insulation.

Sustainability

The main goal of this project is to construct a national model of sustainable design for laboratory buildings. Compared to other laboratory buildings in the United States, the building is expected to consume approximately half the energy than other laboratory buildings. A 6,400 square foot greenhouse on the roof provides additional insulation to the build-ing year-round. The building also has a storm water management system that consists of six 10,000 gallon storage tanks to provide grey-water systems. By this system, over one million gallons of water is saved annually and rain water is reused in the building. The facade system also provides sustainability features. The curved metal shades limit the solar gain during the day and limit the escaping of light at night. With enormous sustainability features in this building, this project is certified to a LEED Platinum.

Structural

FoundationBased on the geotechnical report prepared from Haley & Aldrich, Inc. the structural frame of the building is supported on cast-in-place concrete spread and strip footings.

Gravity SystemThe main floor system design is a structural steel framing with composite concrete slab on metal deck. A typical bay is 21’-8” x 22’-9” and supported by 7 1/2” concrete slab on 3” 20 gauge galvanized composite deck, reinforced with #4 bar in 16” o.c. each way. At greenhouse in the roof, 4” lightweight concrete overlay slab is placed on rigid insulation on 3” cellular concrete slab, reinforced with #4 bar, epoxy coated, at 16” o.c. each way.

Major members of the beam supporting the floor system are W18x35. W21x68 is used as the girder to support beams. The size of columns is varying from W10x49 to W12x136. Most of the columns have a 12 inch depth vary in weight. W12x120 and W12x72 are used mostly in this building. Beside these typical bays, irregular bays are supported other spaces such as corridor, gallery, staircase, and offices where the loads are smaller compared to laboratory. Since this building is a laboratory building, there is a strict floor vibration design criteria. Vibrational velocity should be less than or equal to 3,000 micro-inch/second.

One of the main advantage using a composite beam is to have a greater strength than a bare steel beam. Because of the concrete slab on metal deck, the composite sections increase elastic moment of inertia compared to non-composite. Since a building requires greater values of dead and live loads, Composite beam would be better option. However, it would increase the project cost by adding shear studs.

Lateral SystemThe lateral force resisting system for Life Sciences Building consists of structural steel braced frames. There are sixteen braced frames of varying length and height. Majority of braces used hollow structural section (HSS) 10x10s1/2 and 10x10x3/8. The braced frames are not specially designed for seismic loads. The Figure 11 below shows the location of braced frames throughout Life Sciences Building. The major advantage of concentrically braced frames is to provide high elastic stiffness. However, it reduces architectural versatility on floor plan.

Construction

The construction of Life Sciences Building was managed by Bond Brothers, Inc. The project delivery method was design-bid-build with approximate project cost of $91.6 million. In $91.6 million of the actual project cost, the portion of structural system was $20 million. The unusual combination of exterior facade, brick, granite, and copper, brought the development of performace markups to practice for materials installation.

Due to the tight site and harsh winter condition, the clsoe coordination of material deliveries was required to avoid disruption to the activities on campus. The construction began on September 2008 and the building opened to faculty and researchers during August 2011.

Mechanical

van Zelm Heywood and Shadford, Inc. designed impressive mechanical system to achieve the highest performance in the energy usage of the building. Dedicated outdoor air systems was chosen for primary mechanical system with active chilled beams throughout all laboratory spaces. High efficiency enthalpy wheels are used for heat recovery on air streams.

By integrated with structural and mechanical engineers, a high-performance building envelop system was designed to promote to save the energy using in the building. Spray-on foam insulation and a air/vapor barrier along with triple-glazed windows. Ryan-Biggs, structural engineer, designed an innovative relieving angle support system to support masonry veneer to allow the insulation envelop to run continuously without the interruption of the angle. With the web openings in the steel beams and girders, it allows to run mechanical ductworks and conduits through the structure in the limited space above the ceiling.

Lighting

The building uses ceiling mounted or wall mounted fluorescent lighting fixture based on NEC. Typical Lutron Ecosystem Ballasts are used for the lighting fixture of the building. Lighting controls including switches, day light sensor, occupancy sensor, dimming system, and shade control system are provided to the building as a part of electric work. The curved metal shades are placed on the face of the glass curtain walls at the star towers on the exterior of building. These shades help to limit the amount of light escaping into the night sky and provide shade to limit solar gain during the day.

Electrical

Needham Electric Supply provides electrical utility voltage to the building. The building provides the utilization 480/277V 3-Phase 4-Wire via two switchboard. Both switchboard are located in ground floor of the building. One switchboard distribute 1600amps to the building electrical and mechanical system. The other switchboard, 1200amps, will provide back-up and emergency power for the building.

Fire Protection

The primary steel structural elements in floors and roofs are fire-proofed and Exposed structural steel elements in the greenhouse on the roof is painted with rated intumescent paint.

Transportation

The loading dock is located on the left section of the building underneath of auditorium. Two elevators are provided to the building and there are four staircases including main curved staircase for conveyance to the building.